All Categories & Products

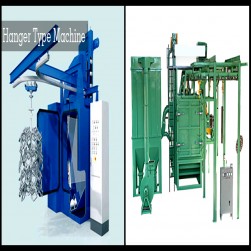

Hanger Type Airless Shot Blasting Machine

Airless Shot Blasting Machine Hanger Type with number of Blast Wheels differing as indicated by the place of work for the wide assortment of workpieces for huge creation yield regarding surface treatment. The overhead transport conveys the work in and out of the impact bureau where quantities of impact wheel are found relying on the sort of the work for achieving a homogeneous completion. Significant pieces of the machine incorporate a shot wheel for giving high creation yield, over the head transport for work passing on and media recuperation, comprise of can lift, screw transport, revolving screen separator, and so forth and residue authority

| Machine Type | Hot Chamber |

| Material to be Casted | Copper, Aluminum |

| Brand | Blast Rooms |

| Automatic Grade | Automatic |

| Voltage | 240 V |

| Surface Finish | Painted |

| Motor Hp | 30 HP |

| No of Blast Wheel | 2 or more than that (Customized) |

| No of Blades | 8 |

| Speed of Blast Wheel | 2800 rpm |

| Shot Velocity | 70-75 mtr/sec |

- During construction projects, shot blasting is also used to clean the outer walls, roads, and floors.

- Shot blasting is often used to clean tanks and pipes underwater before coating or recoating them to stop corrosion.

- ShipYard and ShipBuilding.

- aircraft maintenance and aerospace.

- Foundry for iron, steel, and other metals.

- The casting of aluminum.

- Forgings.

- Rail.

- Foundries.

- fabrication of steel.

- Car and bus murals.

- Wheel cleaning for alloys.

Hanger type airless shot blasting machine manufacturers Jodhpur guarantees that the pivoting spinner is put inside the chamber in this sort of machine. It is the ideal spot where the impact happens. In light of the ideal yield and size of the work, Hanger Type Shot Blasting Machine Manufacturers in Rajasthan can redo all basic viewpoints including various wheels, chambers, and plans.

Types of Hanger Airless Shot Blasting Machine:

• T-Conveyor Type Hanger Shot Blasting Machine

• Closed Loop Type Hanger Type Shot Blasting Machine

• O- Loop Type Hanger Shot Blasting Machine

The machine is intended for programmed proficient shot blasting of Aluminum Casting. The Job is stacked on the Hangers of the Ordering Turn Table. The Job is stacked on the Hanger in the Blasting Cabinet where they are impacted inside the chamber. The speed of the Hanger drives can be directed by AC drives. The bureau is shielded from disintegration by LINERS (Hardened wear plates), mounted on the sidewalls, top, and entryway. The Dust particles created in the framework are gathered in a number of Plated Bags in a residue gatherer. Clean air is depleted through a fumes fan. The Plated Bags are cleaned by Pulse-type Reverse Jet air cleaner controlled through Solenoid Valve, what's more, the gathered residue particles fall in a residue receptacle and taken out for removal every once in a while. The Dust particles created in the framework are gathered in various Plated Bags in a residue gatherer. Clean air is depleted through a fumes fan. The Plated Bags are cleaned by Pulse-type Reverse Jet air cleaner controlled through Solenoid Valve and the gathered residue particles fall in a residue container and set aside out for removal from the effort to time.

| Envelop Size (Dia x Height) | Blast Wheel | Shot Flow Rate (Kg./Wheel/Hour) | Load Carrying Capacity (Kg.) | Wheel Size & Motor (HP) | Total Power Required (HP) |

| 600 x 750 | 2 | 3000 | 300 | 12½” X 5 | 14.5 |

| 600 x 1000 | 2 | 3000 | 300 | 12½” X 5 | 14.5 |

| 600 x 1000 | 2 | 5000 | 300 | 12½” X 7.5 | 22.5 |

| 750 x 750 | 2 | 3000 | 300 | 12½” X 5 | 14.5 |

| 750 x 750 | 2 | 5000 | 300 | 12½” X 7.5 | 22.5 |

| 750 x 1000 | 2 | 3000 | 300 | 12½” X 5 | 16.5 |

| 750 x 1000 | 2 | 5000 | 300 | 12½” X 7.5 | 23.5 |

| 1000 x 1200 | 2 | 5000 | 300 | 12½” X 7.5 | 23.5 |

Ans.

Shot blasting machine prices vary according to the cleaning rate and storage capacity. Shot blasting machines are available in many sizes as per the requirement.

Ans.

In shot blasting most commonly used shot is steel shots. Other blasting media such as cut wire shots, low carbon cut wire shots, glass beads, MS cut wire shots, etc are used in a sand blasting machine in India. Shot blasting machine price in India also vary as per the storage capacity of the tank. Steel shots are reuseable and expensive.

Ans.

Shot blasting machine in India gives surfaces a slightly textured profile. The shot blasting machine does not damage the component. Instead, shot blasting makes the component surface better so that thermal spray coating binds easily.

Ans.

For a shot blasting machine process minimum of 100 PSI air compressor is required. If work with a lower PSI cleaning rate of shot blasting machine in India is decreasing. For the shot blasting process, mostly airless shot blasting machine is used.

Ans.

An Air compressor is required for a shot blasting machine process. For an airless shot blasting machine, an electric wheel is used. Shot blasting machine in India is available in many varieties as per the requirement of the customers.

Ans.

- Railway coaches

- Handicrafts and wood

- Steel pipes

- Stones, Marbles, Granites

- Military

- Shipyards

- Bridges

- Turbines

- Vehicle bodies, Automobiles, Turbocharges

- Windmill

- Casting, and forging

Ans.

Shot blasting is a surface cleaning process. With the help of a shot blasting machine rust, and foreign particles remove easily. Shot blasting machine in India is available both in automatic and manual types.

Ans.

Shot blasting is easy to perform. While blasting it is necessary to wear operator safety wears so it will protect the operator from hazards. A portable shot blasting machine is used in an open area for large size of components. A portable shot blasting machine in India is a manual and semi-automatic type. Airless shot blasting machines are automatic and manual type as well.

Ans.

Shot blasting machine in India is available in many sizes. The weight of the shot blasting machine varies according to the size of the storage capacity tank. As the size of the capacity tank varies, shot blasting machine prices also vary.

Ans.

Sand blasting is a process of removing rust, old paint, burrs, and other impurities from the component surfaces. Sand blasting has a wide range of applications in many areas like wood, glass, steel, plastic, shipbuilding industries, on buildings, medical equipment, etc. Sand blasting machine in India also rough the smooth surface according to the application area.